prev

next

Wheel Loader with Deutz Engine

Description:

This W136 wheel loader is equipped with Deutz engine, and the Deutz engine is famous for its low flow resistance, high filtration efficiency, and compact structure. The Deutz engine used in our bucket loader is equipped with an integrated built-in filtration system, including an oil filter and a cooler.This W136 wheel loader bucket capacity can be 1.8m3or 2.2m3, and the rated payload is 3 tons. Good structure rigidity and larger maintenance space are provided by extended distance between frame articulations. Robotic welding in critical high-stress areas provide highly consistent welds and increased strength. Moreover, this wheel bucket loader consumes 1.67L/hour less fuel when compared with similar loaders.

Loader Parts and Features:

1. Engine: German Deutz engine:

Model: WP6G125E22

Description: Direct injection, water cooling, 4 strokes.

Rated power: 92KW

Rated rotation speed: 2200rpm

Features: a. supercharged intercooling and external EGR technology;

b. Power matching optimization technology, saving up to 19.2% oil when compared with other-brand engines;

c. Integrated built-in oil cooling filtration system; to maintain the filter, users only need to replace the filter element, low maintenance costs;

d. Automatic tensioning front wheel system: smooth transmission, high reliability, maintenance-free, adjustment-free belt, long maintenance cycle;

e. New-type air filter: low flow resistance, high filtration efficiency, compact structure

2. Transmission (Hydraulic transmission) :

The transmission part we use is a ZL30 planetary gearbox, designed with a single-stage hydraulic torque converter that consists of 2 front and 1 rear speeds. The hydraulic power provides smoother shift. 120℃ is the maximum permissible temperature of this hydraulic transmission.

3. Drive axle:

This drive axle delivers reliable performance and extended working life. To withstand internal torque loads and better support the wheel loader, the front axle is rigidly mounted to the frame. And the rear axle can help the wheel bucket loader stably stop on the roughest terrain. The main reducer is equipped with spiral bevel gears with differential, and the hub reducer with planetary gears. The air over oil active brake is a dry caliper brake with brake discs and its brake pads are easy to maintain and better for radiating.

4. Hydraulic Parts:

The hydraulic system for the wheel loader with Deutz engine delivers smooth operation, lower oil temperature and better hydraulic pressure assignment. And best-in-class hydraulic pump, valves, cylinders, joints, seals and hoses are applied for this wheel bucket loader. Before selling, every single loader will be strictly tested for the oil leakage, oil temperature, operation and power.

5. Control Lever:

The wheel loader with Deutz engine has two standard control lever: one is to control the boom lifting up and down and the other to control the bucket tilt and dump. The two levers are very easy to use and all operator has to do is to pull them back or push them forward.

The wheel loader with Deutz engine has two standard control lever: one is to control the boom lifting up and down and the other to control the bucket tilt and dump. The two levers are very easy to use and all operator has to do is to pull them back or push them forward. 6. Joystick:

Joystick is optional for the cab, and it can be moved to four different directions to control the boom and bucket.

Joystick is optional for the cab, and it can be moved to four different directions to control the boom and bucket. Wheel Loader Features:

1. Driving environment:

(1). Ergonomic controls are fully adjustable and designed for low-effort comfort. Switches and controls for various systems are within easy reach of the operator.

(2). Spacious cab provides all-round visibility for improved jobsite safety.

(3). New shock absorbers applied for the joints between engines, gearbox (or transmission), cab and loader frame, which makes the wheel bucket loader work stably and reliably; soundproofing foam and rubber are utilized at the cab bottom and around the water tank, reducing the noise inside the cab.

(4). For the cab, air conditioners and pilot operating system are optional. And there are radio and music USB connector inside the cab.

(5). Regarding the drive axle, its axle housing, main drive gear, differential gear, frame, half axle and the gear of half axle are all enhanced and optimized to have better reliability and extended working life.

(6). The 290mm distance between the cab and rear frame surface facilitates the maintenance of pipes and steering.

(7).The extended distance between the up and down articulated frames makes it very easy to maintain the gearbox and hydraulic system.

(8). The wheelbase is extended up to 2750mm; axle load distribution is reasonable. So this wheel loader features good reliability and stability.

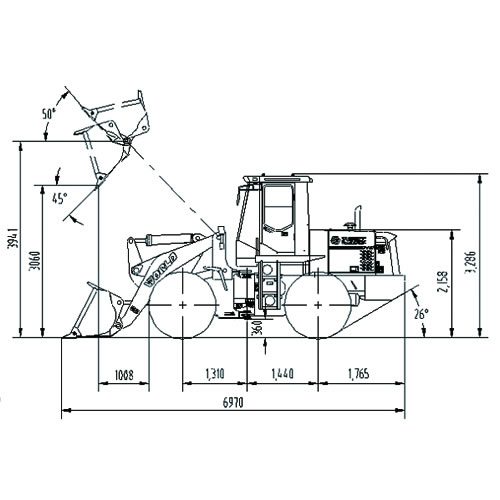

Wheel Loader Specifications:

| Resource allocation of W136 with air condition | |

| Items | |

| Bucket capacity(CBM) | 1.8 or 2.2 |

| Rated load(kg) | 3200 |

| Max.Breakout Force(KN) | 100±5 |

| Max.Traction(KN) | 97±5 |

| Forward Speed 1(KM/H) | 0-10.8 |

| Forward Speed 2(km/h) | 0-32.5 |

| Reverse Speed(km/h) | 0-14.5 |

| Max Dumping (mm) | 3060±50 |

| Max.Dumping Reach(mm) | 1020±50 |

| Min.turning radius(mm) | 6005±50 |

| Min .Clearance Over Ground(mm) | 360±20 |

| Wheel Base(mm) | 2750±30 |

| Tread (mm) | 1800±10 |

| Total Hydraulic Cycle Time(s) | ≦10.3 |

| Full Bucket Lifting Time(s) | ≦5.6 |

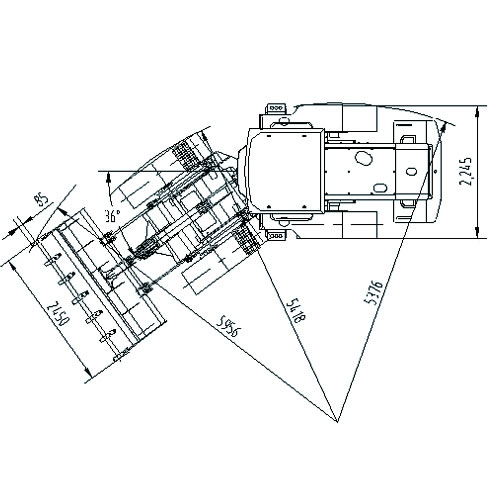

| Overall Dimensions(mm) | L:6950×W:2245×H:3228 |

| Operating Weight(kg) | 10000±100 |

| Diesel Engine | |

| Brand | Deutz WP6G125E22 |

| Type | Direct injection ,water cooling ,4strokes |

| Rated Output(kw) | 97 |

| Rated Speed(rpm) | 2200 |

| Max.Torque(N.m) | 500 |

| Transmission | |

| Type | Planetary type |

| Rated Input Speed(rpm) | 2200 |

| Transaxle And Tire | |

| Rear Axle Oscillation | Center oscillation |

| Oscillating Angle Of Rear Axle(°) | 12 |

| Pressure Of Tire(Mpa) | 0/28-0.32 |

| Working Hydraulic System | |

| Working Pump Type | Gear pump |

| Working Pressure(Mpa) | 16 |

| Lifting Cylinder Bore ×Stroke(mm) | 125×816 |

| Tilting Cylinder Bore×Stroke(mm) | 140×553 |

| Steering System | |

| Steering Pump Type | CBY2050 |

| Working Pressure(Mpa) | 10 |

| Steering Cylinder Bore*Stroke(mm) | 80×340 |

| Max.Steering Angle(°) | 36 |

Optional Parts:

1. 2.2 m3 coal bucket |

2. Rock bucket |

3. Log grapple |

4. Pallet fork |

5. Joystick